Dough Sheeter Manufacturers in Bangladesh

HCS Enterprises is a leading name among Dough Sheeter manufacturers in Bangladesh, known for its excellence in producing high-quality dough sheeting equipment. Our Dough Sheeters are engineered to ensure precise dough thickness and uniformity, crucial for achieving top-notch baked goods. By utilizing advanced technology and durable components, we deliver machines that offer consistent performance and reliability. As a prominent Dough Sheeter manufacturer in Bangladesh, HCS Enterprises is dedicated to providing equipment that enhances efficiency and quality in baking operations. Choose us for reliable and high-performance Dough Sheeters that meet your bakery’s needs.

Dough Sheeter Suppliers in Bangladesh

In the realm of Dough Sheeter suppliers in Bangladesh, HCS Enterprises stands out for its commitment to quality and service. We supply a diverse range of Dough Sheeters designed to meet the varied requirements of bakeries and food processing facilities. Our equipment is built to deliver precise and consistent results, ensuring smooth and efficient dough processing. As leading Dough Sheeter suppliers in Bangladesh, we focus on providing reliable products and excellent customer support. Partner with HCS Enterprises to experience superior performance and dependability in every Dough Sheeter we offer.

Dough Sheeter Exporters in Bangladesh

HCS Enterprises excels as a top choice among Dough Sheeter exporters in Bangladesh, offering high-quality bakery equipment to a global market. Our Dough Sheeters are meticulously designed to provide consistent dough thickness and superior performance, making them ideal for various baking applications worldwide. As a trusted Dough Sheeter exporter in Bangladesh, we ensure that our products adhere to international standards for quality and reliability. Choose HCS Enterprises for your international dough sheeting needs and benefit from our commitment to excellence and efficient export services. Discover how our Dough Sheeter solutions can enhance your global baking operations.

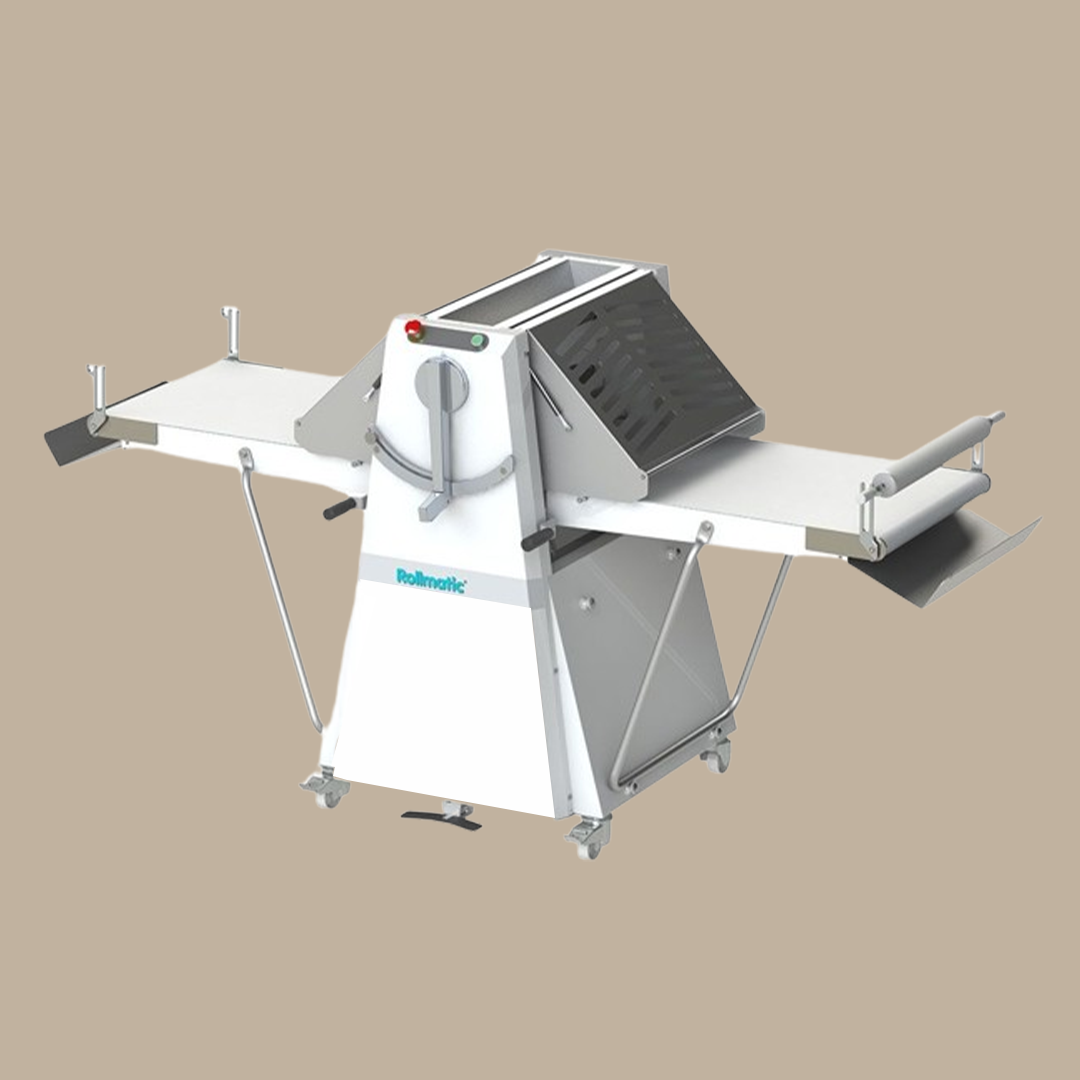

Dough Sheeter

This piece of kitchen equipment allows the operator to feed a ball of dough into one end, where it will then flatten the contents into a large, even sheet. This done by manually or automatically, depending on the machine and the size can range from a small tabletop product to a large scale, stand-alone Sheeter.

The Sheeter made up by two or more rollers that will rotate to compress the dough.

The dough passes from at least one gauging roller or a conveyor, which reduces the dough to the right thickness.